Project Overview

Client: Arvind Mills

Location: Gandhinagar, Gujarat

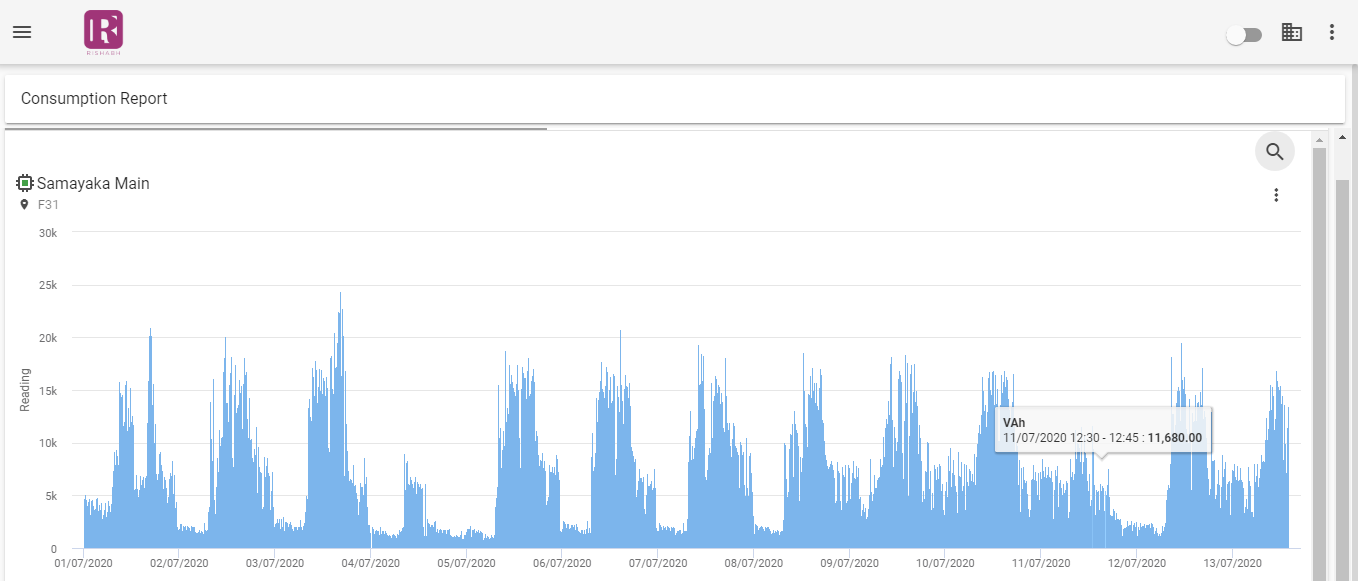

Application: Energy data monitoring of remote location

Product: marc.cloud software (EMS)

Load Monitored: 10 Nos.

Client

Arvind Limited (formerly Arvind Mills) is a textile manufacturer and the flagship company of the Arvind Group. It is India's largest denim manufacturer apart from being the world’s fourth-largest producer and exporter of denim. Its headquarters is in Naroda, Ahmedabad, Gujarat, India. It has units at Santej (near Kalol) manufacturing cotton shirting, denim, knits and bottom weights (Khakis) fabrics.

Premise

The remote switch yard (2.5 km) monitoring, required dedicated manpower to monitor and record the energy data reading from individual energy meters. Apart from the distance, the multiple numbers of meters was complicating the data recording process.

The recorded data was written in log sheets which was not precise

and time synchronized across multiple points of measurement.

Analysis of data was on limited parameters and solely dependent

on a person, making errors.

The ESL approach

ESL team audited the plant setup and consulted the team to deploy an energy management system with a central data acquisition system hosted on a server after a full due diligence of the wiring network. The cost-benefit analysis showed a very quick ROI(Return On Investment) thus getting a go ahead from the senior

leadership team for the implementation.

The management additionally wanted real time data acquisition with no manual intervention in its collection thus bringing more accuracy of measurement and reduction in man-power in the process. This was directly achieved by the deployed platform.

The ESL team could further reduce the project cost by using the existing energy meters and sensors deployed in the plant and integrating it with the energy management platform. Additionally, by selecting the right converters the system was designed to work even in a power outage condition at switchyard, which helped the client do an in depth root cause analysis of the event of the power loss. Finally the team used high speed optical fibre converters for long distance application (~2.5km) due to unavailability of LAN connectivity.

Results

- Automatic data recording, monitoring, and analysis.

- Reduction in manpower.

- Utilisation of already deployed meters and sensors.

- Time stamped data to trace and analyse events

- Proven energy cost saving post 1 month of deployments

- Co-relation of energy cost data to production data

- Total control over incoming as well as outgoing feeders