The Problem

Annual Maintenance Contract (AMC) used to extend warranty among other support and services, can be a source of dispute between the AMC company and the client. This is due to in-applicability and exclusion of the power quality for AMC in the terms and conditions. The damage and subsequent downtime, of any sort in the industrial machines can be a cause of the catastrophe. In such circumstances, manufacturing industries sustain additional fiscal losses.

The company providing AMC sometimes speculate that poor power quality is the causes of equipment deterioration, while the client company disagrees as there is no log of data. This leads to contradiction in the two companies and eventually causing monetary and effort loss to the client.

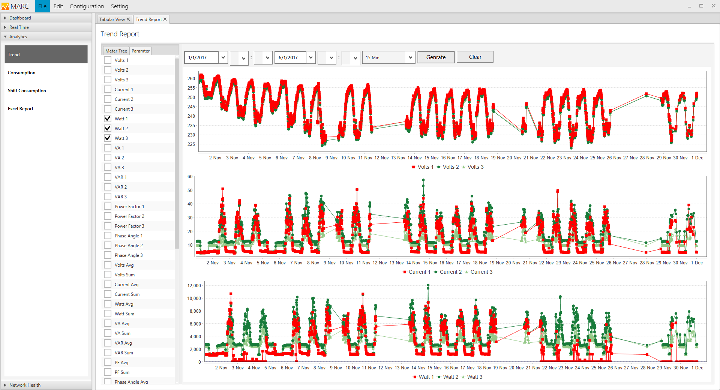

Energy Management System (marc) has made easy to cease the AMC disputes

The Solution

Without proper reports consisting of energy usage throughout the machine operating time and power quality reports, it is almost impossible to deduce the prime cause of machine failure due to electrical faults.

An energy management system (EMS) can provide metering, submetering and monitoring functions that allow facility managers to gather data that allows them to make more informed decisions about energy use. marc is a very effective solution as it is an energy management system; which focuses on best practices of accurate data acquisition, energy monitoring, and platform independent data analysis. marc additionally has an alarming system in the form of emails if any parameters conditions meet the trigger set points.

The usual conflicts of a AMC company and the client company can easily be sorted by marc as it records the energy-relevant data and generates reports of the same. The company is made aware if the power quality is ever reduced and the management can consequently make amendments. Lastly the company can predict a downtime by also effectively monitoring the energy and power quality trends on the machine.

The Benefits

- Log to trace energy data and historical trends.

- Accurate power quality monitoring in real-time.

- Granular in-depth review of facility energy data

- Better information to produce as a proof to the service provider

- Comparison of energy usage across similar facilities over time

- Ability to identify and eliminate loss of energy

- Enhanced efficiency of electric utility service