The Problem

Metal fasteners like screws, nuts, bolts, and rivets are used on a large scale in a myriad of applications. Though these fasteners appear to be unimportant and small on the contrary they perform a very major role in giving strength to gigantic structures like bridges, buildings, rail tracks and electrical machines like generators and turbines. These fasteners are used for making joints, holding objects and in conjunction with mating bolts. So the overall strength of fasteners is there toughness.

Manufacturing process

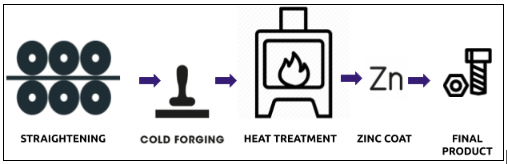

Fasteners like nuts and bolts or studs undergo extreme manufacturing processes like straightening, cold forging, threading, heat treatment or galvanizing. In the process of straightening raw steel wire and after cold forging, the material loses its property of toughness and might become brittle. Therefore it undergoes a very essential process called heat treatment during which the bolts are heated at desired temperatures to rearrange their molecular structure and regain robustness.

To reconstruct the molecules of steel to make it more stronger, bolts (fasteners) undergo heat treatment. For this, high temperature electric furnaces are used. The heat treatment is called tempering. Tempering is a three-stage method, and any deviation in the applied temperature may lead to brittle fasteners. This requires continuous monitoring and recording of furnace temperature. Hence, a device capable of recording these readings at different instants of time is required.

The Solution

In the process of tempering, the type and condition of tempering equipment and temperature uniformity plays a critical role. Tight temperature uniformity, typically ±5.5°C is required throughout the load, with ±2.75°C preferred especially for high-speed and precipitation hardening steels. It is important to know what is happening to the part's microstructure at the selected tempering temperature.

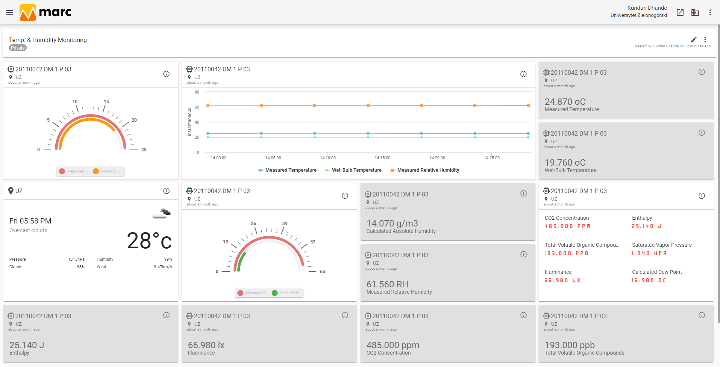

A solution demanded by the application is one that can record temperatures from 6 different inputs of three furnace zones. To cater to this need, temperature sensors along with the marc.gateway equipment with marc are used. Continuous monitoring of readings can be done on the marc software. The data can be logged according to user-settable time intervals. Temperature inputs for every received sample are plotted against time. The graphical representation of the temperature value is then used for reporting and analysis purposes.

The Benefits

- Ease of recording and analysis reduces chances of errors due to human intervention

- Data on marc can be viewed in various forms viz. linear diagrams, digital indicators, analog views, graphs, tables, and these views can be switched manually which helps understand data more effectively

- Data can be downloaded in .csv format, which enables plotting of graphs and printing for reporting and documentation

- The flexibility of operation by providing user-settable input parameters and time intervals

- Defects in the finished product due to an inappropriate temperature in the furnace can be traced down easily with the help of records