Project Overview

Client: PharmaZell

Location: Chennai, Tamil Nadu

Application: Automatic energy data collection integrated with the ERP system

Product: marc.desktop software (EMS)

Area: 3 Plants surrounding the airport

Client

PharmaZell (India) Pvt. Ltd. was constructed as a greenfield site in 1995 in the Special Economic Zone (SEZ) of the Madras Export Processing Zone (MEPZ). It was initially built as a 100% affiliate of the German site to produce amino acids and their derivatives using water-based chemistry only.

Due to its proximity to the International Airport of Chennai and one of the largest harbours of India, as well as ease of access to a pool of well-trained workforce at their Chennai site, they have grown multi-fold since incorporation and now handle a wide range of chemicals on an area three times as large as it was at the beginning.

Premise

They used a manual system of energy consumption data collection and data entry in the company ERP system to generate a detailed MIS report. Also, manual collection required extra manpower and effort.

The existing process was prone to human errors making it less accurate and the data collected was not time synchronized.

The plant faced penalties for exceeding their Contract Demand (MD levies) & had poor power quality.

The ESL approach

After implementation of MARC, the energy-related data was logged automatically, substituting and eliminating the manual data collection and data entry operation. It saved time and effort which was required for logging the data & generating MIS

reports.

Uploading data to the ERP became easy & error free to rely upon. By that, MIS reports became authentic thus increasing their credibility. Their core report of production vs energy consumption analysis became accurate and automated.

Now, PharmaZell can do detailed costing of each item they produce through specific energy consumption report and levying the energy cost on the product being produced.

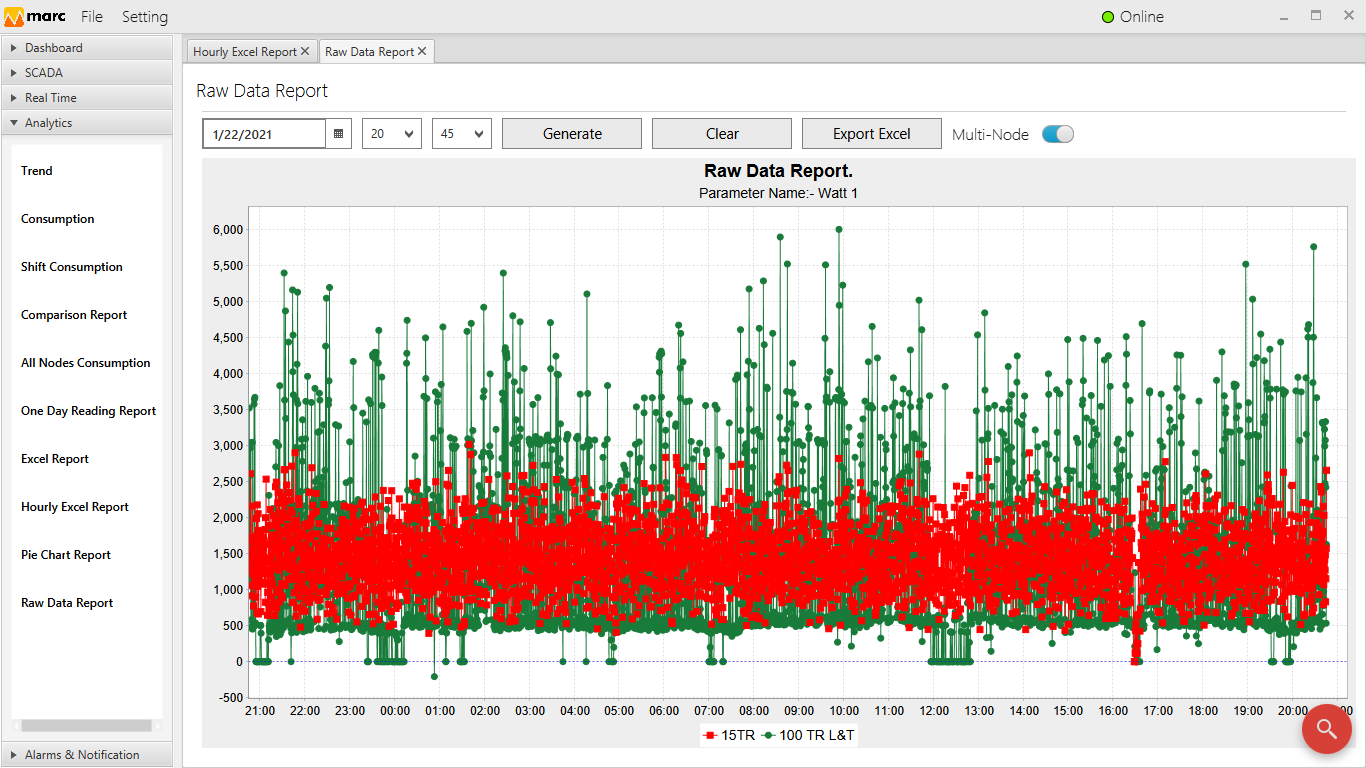

ESL further consulted PharmaZell for the proper selection of hardware devices at respective loads for energy parameter monitoring e.g. We installed Lumel's ND20 Multifunction meter at the main incomer to monitor THD and individual harmonics. The detailed energy parameter monitoring helped the client to understand the harmonics level & then eventually led to its control. The controlling saved THD penalties offloaded by the utility.

The multi-function meters were installed at each load to monitor the real-time energy-related data. This resulted in understanding the real-time energy consumption & pro-active controlling, thus maintaining the MD (Maximum Demand).

Results

ESL's comprehensive approach assisted the client to find and act on their energy OPEX saving potential. The discrete goals achieved are as follows-

- Automatic data recording, monitoring and analysis.

- Automated and timely reports.

- High accuracy of data, as human errors were eliminated.

- Reduction in manpower.

- Power factor & MD maintenance at the required levels.

- Proven energy cost saving after 1 month of deployment.