Project Overview

Client: Ratan India Power Limited (RPL)

Location: Amravati, Maharashtra

Application: Operational & Expense Analysis

Product: marc.desktop software (EMS)

Area: 1350 acres

Client

Amravati Thermal Power Plant in situated in Nandgaonpeth, 13 kilometres from Amravati city, Maharashtra in India. This coal based thermal power plant spread over an area of 1,350 acres at MIDC Industrial Area. Amravati Plant comprises of 5X270 MW, best-in-class, BHEL units with total installed capacity of 1350MW.

The company has 25 years power purchase agreement with Maharashtra State Electricity Distribution Company Limited (MSEDCL). Amravati Plant had 100% plant availability factor and is currently operating at a plant load factor of 86%.

Amravati Thermal Power Plant has coal linkages from Coal India Limited (CIL) subsidiaries. Company owns and operates railway line between Walgaon and Amravati power plant for coal supply to the plant. Amravati Thermal Power Plant also comprises of a residential township for its personnel.

Evacuation of power from the Power Plant is being through a 104 Km long 400 kV DC Quad Moose line from Amravati Project to Akola, Maharashtra.

Premise

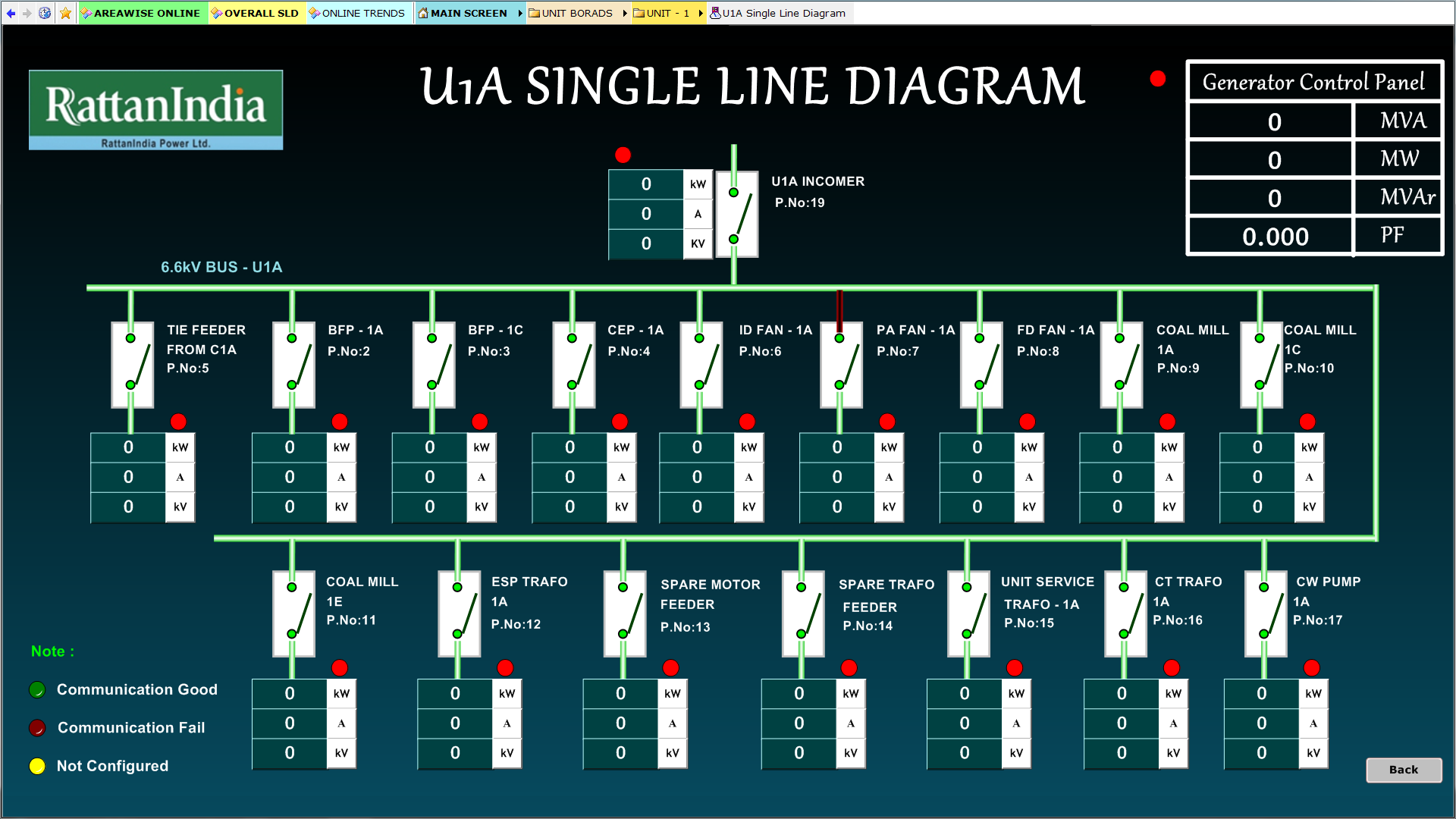

The Amravati Thermal Power Plant is made up of a 5X270 MW unit=1350 MW.

The auxiliary load usage of this facility equated to 10%+ of the 1350 MW output.

The power plant contains various inductive loads, such as turbines, which led to a decline in power quality.

Consequently, issues arose with power factor, reactive power, and harmonics not being adequately controlled.

To address these challenges, there was a requirement for a monitoring system to oversee power factor.

However, the monitoring of auxiliary load parameters proved to be problematic.

This issue resulted in significant power losses. Consequently, there was a need for data to facilitate an expense analysis

The ESL approach

The implementation of MARC for 520 meters demonstrated many advantages to the operations. All energy-related data was automated and free of human intervention.

Manual data collection was eliminated which resulted in saving time, effort & bringing higher accuracy. The reporting system foremost was made more sophisticated as digital reports were generated, making it easier to process, analyse, and act.

The report format of Thermal Power Plant was highly customised, and they expected the EMS software to give reports in their formats. This expectation was fulfilled by MARC as all the reports which were generated by the software were built in the legacy formats.

The comparison amongst the reports was achievable since the received data was easily accessible. This was possible due to the digital copy documentation.

Based on the data it was easy to make operational and expense analysis. They could analyse which auxiliary load is consuming more power. Accordingly corrective action is taken and auxiliary load power consumption was significantly reduced by more than 2.4% By implementing “marc", the overall system is optimised.

Results

The estimated goals were achieved by ESL's comprehensive approach and the in-depth understanding of issues related to energy monitoring. The benefits achieved were as follows-

- Marc software monitors the overall power generation and power consumption.

- To track the power consumption, marc helped to get time-stamped data.

- Online data assessment by soft documentation is achieved.

- Reports are in expected and customised format. Hence comparisons became achievable.

- Alarm & Notification feature keeps an eye on the important parameters like current, pf etc.

- Analysis of the operational aspects and expenses associated with the auxiliary load is achieved.

- 2.4% of 1350MW power was saved per year against auxiliary load.